How Explosion-Proof Air Conditioning Works

In 2023, over 40% of industrial explosions worldwide were caused by bad climate control. This shows how important explosion proof air conditioning is. In places like oil refineries, regular air conditioners aren’t safe. Explosion proof HVAC units are made to work safely in dangerous areas.

These systems are not just better versions of regular air conditioners. They are built to avoid fire risks.

Explosion Proof Air Conditioning

Explosion Proof Air Conditioning

In places like the UAE’s petrochemical facilities, explosion proof ac keeps things cool safely. Unlike normal air conditioners, these units have special designs. They have sealed boxes, special electrical parts, and ventilation that keeps sparks in.

Knowing how these systems work is crucial. It helps protect workers and things in risky places.

Key Takeaways

- Explosion-proof systems prevent ignition in zones with flammable materials.

- Explosion proof air conditioning units comply with strict UAE safety regulations.

- These systems use containment, heat control, and spark-free components.

- They’re vital for industries like energy, chemicals, and manufacturing.

- Proper installation ensures compliance with global and local standards.

Understanding the Need for Explosion-Proof Air Conditioners

In places with flammable gases, vapors, or dust, regular air conditioners are dangerous. That’s why intrinsically safe air conditioner tech is key. These units, like ex proof air conditioner models, stop sparks that could cause explosions. They are crucial in risky environments.

What Makes an Environment Hazardous?

Hazardous spots are sorted into three groups:

- Class (e.g., Class I for flammable gases)

- Zone/Division (e.g., Zone 1 for areas with frequent hazards)

- Group (defines specific substances like propane or methane)

Places like oil refineries or chemical plants need explosion proof hvac system solutions.

Safety Risks in Explosive Atmospheres

Normal HVAC units can spark and ignite in dangerous conditions. For instance, a faulty compressor in a paint mixing area could start a fire. Industries like petrochemicals or grain processing use ex proof air conditioner designs to avoid these dangers.

Regulatory Requirements for Hazardous Areas

Managers must follow strict rules like ATEX approved air conditioning units certifications. In the UAE, following local and international rules like ATEX is a must. Not doing so can result in fines, shutdowns, or worse.

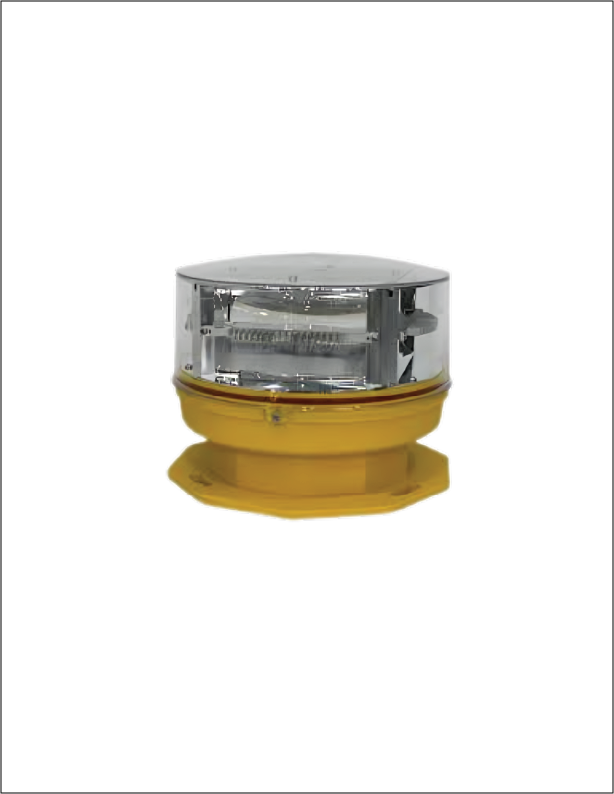

Core Components of an Explosion-Proof Air Conditioner

Explosion proof air conditioner systems have two main parts for safety in dangerous places. The internal unit works inside safe areas like clean rooms. It cools the air and keeps risks away. The external unit handles heat outside, creating a safe space for cooling.

Important parts include strong flame proof ac housings made from non-sparking materials. These enclosures keep electrical parts safe from sparks. Compressors and motors are made with flame-resistant alloys to reduce heat.

Electrical systems use sealed wiring and protected circuits. This stops spark risks in dangerous atmospheres.

- Internal Unit: Filters air and distributes cooling via corrosion-resistant ducts.

- External Unit: Manages heat expulsion with explosion-proof fans and vents.

- Sealed Components: Double-layered casings contain potential sparks, meeting ATEX and IECEx standards.

Brands like atexxo air conditioner make these systems safe and efficient. Every part, from the compressor to the heat exchanger, is tested for extreme conditions. This ensures safe cooling in places like oil refineries or chemical plants.

The Science Behind Explosion-Proof Technology

Explosion-proof air conditioners use three main principles for safety in dangerous places. These principles turn regular coolers into flameproof units ready for extreme conditions. Let’s explore how each part works together to stop disasters.

Containment Principles

Heavy-duty enclosures act as barriers during internal explosions. They are built for explosion-proof window units to handle pressure surges. Engineers plan flame paths and gaps to stop sparks from getting out.

Regular pressure tests make sure even flameproof split ac models meet strict safety standards.

Heat Dissipation Methods

Advanced cooling loops remove heat without starting fires. Explosion proof ac systems use strong heat exchangers and thermal sensors to control temperatures. Window units and split systems have airflow designs to prevent hotspots in flammable areas.

Spark Prevention Mechanisms

Electrical parts are shielded with encapsulation or oil-filled insulation. Some systems use pressurized air to block flammable gases from hot parts. These innovations show why explosion proof air conditioner price reflects special engineering—every part is designed to prevent fires.

These methods make explosion-proof HVAC systems reliable for UAE’s industrial settings. The science ensures safety without losing performance, making them essential for high-risk facilities.

Key Features of Internal Units in Explosion-Proof HVAC Systems

In places like chemical labs or oil refineries, the internal unit of an explosion-proof hvac unit keeps operations safe. It’s made for areas needing strict safety rules. Systems like the explosion proof window air conditioner use three main features to keep things safe and working well.

Heavy-Duty Corrosion-Resistant Housing

These units are made from 316L stainless steel or powder-coated aluminum. They stop chemical corrosion and prevent flames from spreading. Their sealed design meets IECEx standards, keeping sparks in even when pressure changes.

Explosion proof air conditioners manufacturers make these housings strong. They can handle extreme temperatures and vibrations.

- Metal thickness: 3mm+ for flame resistance

- Gaskets rated for -20°C to +60°C

- Non-sparking surface finishes

Pressure Relief Port Systems

Pressure relief ports are a safety feature. They open up when gas or flames build up inside. These vents:

- Release pressure through precisely engineered nozzles

- Direct flames away from ignition sources

- Maintain structural integrity after venting

These systems follow UAE safety codes for explosion proof portable air conditioner setups.

Advanced Filtration Technology

The filtration in these units is more advanced than usual. HEPA/ULPA filters catch 0.3-micron particles. Static-dissipative materials also stop sparks from forming. This protects both the machines and people’s health.

| Feature | Description |

|---|---|

| Corrosion Housing | Material: 316L stainless steel, ASME-certified |

| Pressure Relief Ports | ISO 80079-compliant vent design |

| Filtration | HEPA/ULPA + electrostatic charge elimination |

These features make sure explosion proof hvac units work well in places like petrochemical plants and pharmaceutical labs. Keeping these parts in good shape helps them last longer. It also meets OSHA rules for dangerous areas.

External Unit Design and Functionality

The external unit of an explosion proof split air conditioner is key for safety and efficiency. It’s made for tough environments like the UAE, handling sandstorms, humidity, and extreme heat. It meets strict safety standards, with every part designed to avoid ignition risks.

- Weather-resistant enclosures made of corrosion-proof materials

- Sealed joints to block dust and moisture

- Reinforced mounting brackets for stability during storms

Daikin explosion proof air conditioner models have advanced compressors and fans. They use flame path designs to keep sparks in. This system keeps the refrigerant cool and prevents heat buildup that could ignite dangerous fumes.

Communication between indoor and outdoor units uses non-sparking wiring and sealed connectors. Installation must be strategic, away from flammable materials and securely anchored. Regular checks keep the explosion proof air conditioner safe and running well in hazardous areas.

Certification Standards for Explosion-Proof Air Conditioning Units

Choosing explosion proof hvac systems for hazardous areas is crucial. You need to make sure they meet global and local safety standards. Here’s how to understand the important certifications.

ATEX Certification Explained

ATEX certification means the equipment is safe for explosive atmospheres. Look for atexxo air conditioner models with the “Ex” mark. This shows they follow EU Directive 2014/34/EU. Labels like “Ex d IIC T4 Gb” indicate protection levels against sparks, gases, and temperatures. Always check the certification number on the official ATEX database.

IECEx and Other Standards

The ex proof air conditioner market also follows IECEx for international use. This system uses “Ex” certificates in 60+ countries. Important things to check include: – Equipment category (Zone 1/2 for gas, Zone 21/22 for dust) – Temperature class (T1–T6) matching flammable material ignition points – Approval for Group I (surface mining/oil/gas) or Group II (industrial) use

UAE Compliance Requirements

In the UAE, all explosion proof hvac systems must meet certain standards. These include:

- Abu Dhabi’s OSHAD regulations for hazardous zones

- Dubai Municipality’s HVAC safety bylaws

- Emirates Metrology Institute (EMI) equipment approvals

Suppliers must provide Emirates Authority for Standardization and Metrology (ESMA) certification copies. Regular inspections by UAE authorities ensure ongoing compliance with local fire and safety codes.

Industries and Applications Requiring Explosion-Proof AC

Explosion proof hvac units protect important work in many fields. In the UAE and nearby, they are key for places with flammable stuff or explosive dust. They really help out in these areas:

- Oil & Gas: Refineries and sea platforms need these units to stop fires in Class I zones.

- Chemical Manufacturing: Places making solvents or plastics use these units to keep things safe and cool.

- Pharmaceuticals: Cleanrooms need to control humidity and stop sparks. They often use explosion proof portable air conditioner for labs.

- Mining: Underground and coal places use tough portable units to handle methane risks.

- Emerging Tech: UAE’s green hydrogen and lithium battery places use special units to meet ISO standards.

| Industry | Main Hazard | Recommended Unit Type |

|---|---|---|

| Petrochemical | Flammable vapors | Zone 1 certified air conditioning units |

| Food Processing | Grain dust | Explosion-proof portable systems |

| Data Centers | Electrical hazards | Fire-resistant HVAC enclosures |

| Automotive Paint Shops | Solvent fumes | Low-temperature ac units |

| Marine | Moisture and salt corrosion | Corrosion-resistant hvac units |

In the UAE’s growing energy field, portable air conditioners are key for cooling in the desert. They protect workers in refineries and keep labs precise. These systems are made for each place’s special risks. As more industries move into risky areas, picking the right units keeps everyone safe and working well.

Comparing Top Manufacturers: Daikin, Carrier, and Friedrich Explosion-Proof Solutions

In the UAE, businesses look for top-notch explosion-proof air conditioning. They want it to last long and work well. Here’s a look at what daikin explosion proof air conditioner, carrier explosion proof air conditioner, and friedrich explosion proof air conditioner offer:

Performance Specifications

- Daikin models have high cooling power (up to 24,000 BTU/h) and use inverter tech for better efficiency.

- Carrier systems are known for being quiet (under 55 dB), perfect for places where noise is a problem.

- Friedrich units are designed to be small but still pack a punch, great for tight spaces.

Durability and Reliability Factors

A UAE-specific quote from manufacturer data:

“Materials must withstand 50°C+ temperatures and high humidity without corrosion.”

- Daikin uses stainless-steel casings for chemical resistance.

- Carrier compressors are built for 24/7 use in extreme heat.

- Friedrich’s housing keeps dust out, important for desert areas.

Warranty and Support Services

- Daikin offers 5-year warranties with UAE-based service centers.

- Carrier includes extended parts coverage for ATEX-certified units.

- Friedrich provides remote diagnostics via their app for quick fixes.

When deciding between these brands, consider the explosion proof air conditioner price and what you need long-term. Local support and how well the unit works in harsh environments are key. These often outweigh the initial cost in high-risk fields.

Installation Considerations for Intrinsically Safe Air Conditioners

Setting up intrinsically safe air conditioner systems in risky spots needs careful planning. First, check UAE hazardous area types and what structures can hold. Make sure walls or roofs can handle the weight of explosion proof window units. These units are heavier than usual ACs by 30–50%.

- Contractor Qualifications: Only hire technicians certified under UAE Federal Decree-Law No. (21) 2015 for hazardous equipment installation

- Electrical Safety: Use heavy-duty conduit rated for Class I, Division 1 areas and ensure grounding rods are spaced ≤10 meters apart

- Clearances: Keep a 1.2m distance between explosion proof split air conditioner condensers and flammable material storage areas

| Feature | Window Units | Split Systems |

|---|---|---|

| Structural Support | Reinforced wall anchors required | Outdoor condenser mounting pads |

| Electrical Needs | IP66-rated junction boxes | Isolated circuit breakers |

| Airflow Requirements | 50cm clearance on all sides | Custom ductwork for hazardous zones |

“Proper installation isn’t optional—it’s the first line of defense against electrical arcs and gas leaks,” says UAE Safety Authority Engineer Fatima Al-Mansoori.

After installation, do dielectric strength tests as per IEC 60079-0 standards. Use certified explosion-proof junction boxes for all electrical connections. For explosion proof window air conditioner systems, make sure drainage hoses slope down at 5°. This prevents flammable vapors from building up. Keep all test certificates and inspection reports for UAE Ministry of Energy audits.

Maintenance Best Practices and Safety Protocols

Keeping explosion proof hvac systems in top shape is key for safety and longevity. In hazardous UAE areas, regular maintenance is more than just a routine—it’s a must. Here’s how to ensure your equipment meets safety standards and works well.

Routine Inspection Checklist

- Daily Checks: Look for cracks or leaks in seals, vents, and cooling units. Clean the flameproof split ac surfaces every day.

- Monthly: Swap out filters in explosion proof air conditioner units. Also, test pressure relief valves and check electrical connections.

- Quarterly: Check if insulation is intact and calibrate temperature sensors. Follow the manufacturer’s guide for lubricating moving parts.

- Annual: Have a full system check by certified techs. Also, update safety records for UAE compliance.

Common Issues and Quick Fixes

- Cooling Decline: If filters are clogged or vents are blocked, efficiency drops. Clean filters and ensure good airflow.

- Noises or Vibration: If fans are off or parts are loose, this happens. Fix loose parts or replace worn ones.

- Control Errors: If control panels malfunction, they need recalibration. Don’t try to fix electrical issues yourself.

When to Call Professionals

For explosion proof ac electrical issues or to ensure compliance, call certified techs. Look for UAE-licensed pros with ATEX or IECEx training. Never fix live systems—turn them off first.

“Maintenance isn’t optional here. Even small neglect can turn a flameproof split ac into a risk,” says UAE safety inspector Fatima Al-Mansoori. “Stick to schedules and document everything.”

Keep detailed records of all maintenance. These logs are crucial for UAE safety checks and tracking system health. Always prioritize safety: use insulated tools and follow lockout-tagout rules during inspections.

Conclusion: Investing in Safety and Efficiency with Explosion-Proof Air Conditioning

Choosing the right explosion proof air conditioning units is key for businesses in hazardous UAE areas. Brands like Daikin, Carrier, and Friedrich provide safe and effective solutions. Look for ATEX and IECEx compliance when picking explosion proof air conditioners manufacturers.

The initial cost of explosion proof air conditioner price might seem high. But, the long-term benefits of less downtime and longer equipment life make it worth it.

New technologies, like IoT monitoring and energy-saving designs, are changing these systems. For UAE facilities, smart features can boost safety and lower costs. Make sure the atexxo air conditioner meets UAE safety standards before you install it.

Regular upkeep and expert checks are crucial to avoid problems in risky places. Facility managers should work with certified installers for the best results. Compare explosion proof air conditioning units based on energy use, warranty, and local support.

Putting safety first today protects people and assets. It ensures reliable cooling, even in dangerous areas.

FAQ

What is an explosion-proof air conditioner?

An explosion-proof air conditioner is made for places with flammable gases or dust. It’s built strong to stop fires and keep temperatures safe.

How does an explosion-proof HVAC system differ from regular units?

Explosion-proof HVACs are made to hold sparks or flames inside. They use special parts and wiring for safe use in dangerous places.

What kind of environments require explosion-proof AC units?

Places like oil rigs, chemical plants, mines, and labs need these ACs. They’re used where flammable stuff could cause explosions.

Are there specific certifications for explosion-proof air conditioners?

Yes, they need ATEX and IECEx certifications. These show they meet safety rules in risky areas.

What are the benefits of using a Daikin explosion-proof air conditioner?

Daikin’s units are energy-saving, reliable, and safe. They also have great support and warranties.

How often should explosion-proof HVAC units be inspected?

Check them daily, change filters monthly, and do electrical checks every three months. This keeps them working well and safely.

Can you install a standard air conditioner in a hazardous area?

No, regular air conditioners aren’t safe in dangerous areas. They don’t have the right safety features to stop fires.

What is the price range for explosion-proof air conditioning units?

Prices vary by size, features, and brand. They’re more expensive than regular units because of their special design.

What maintenance practices are recommended for explosion-proof air conditioning systems?

Regular checks, quick fixes for problems, and following safety rules are key. This keeps the system safe and working right.

Are there portable options for explosion-proof air conditioning?

Yes, there are portable explosion-proof air conditioners. They’re flexible and cool areas safely without losing safety standards.

Contact Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

![Explosion Proof Window Air Conditioner [BKT-2.5 C] | Explosion Proof Air Conditioner in UAE](https://alarmannunciator.ae/wp-content/uploads/2025/02/Untitled-1ex-proof-window-ac-300x388.webp)