Explosion-proof lighting is a specialized type of lighting designed to operate safely in hazardous environments where there is a risk of explosions due to the presence of flammable gases, vapors, dust, or fibers. These lights are engineered to prevent the ignition of explosive materials in the surrounding atmosphere, ensuring the safety of the environment and the people within it.

Types of Ex-Proof Lighting.

- LED Explosion-Proof Lights

- Fluorescent Explosion-Proof Lights

- Incandescent Explosion-Proof Lights

- HID (High-Intensity Discharge) Explosion-Proof Lights

- Portable Explosion-Proof Lights

LED Explosion-Proof Lights.

LED explosion-proof lights are engineered for use in hazardous environments where there’s a risk of explosive gases, dust, or vapors. These lights are built to withstand extreme conditions and prevent any sparks or fires that could ignite dangerous substances. Here’s a closer look at their features and benefits:

1. Robust Construction : The housings of explosion-proof LED lights are constructed from heavy-duty materials like aluminum or stainless steel, designed to endure harsh environments. They are sealed tightly to prevent any ingress of dust or moisture, meeting strict IP (Ingress Protection) ratings. This rugged build ensures durability in the face of high-impact situations and corrosive elements.

2. Safety Standards : To ensure safety, these lights are certified according to international standards like ATEX (Europe) or NEC (North America). These certifications confirm that the lights have been tested and approved to operate safely in hazardous areas. They are designed to eliminate the risk of ignition, thereby protecting both the environment and personnel.

3. Energy Efficiency : Unlike traditional lighting, LED explosion-proof lights are highly energy-efficient. They use LED technology, which not only consumes less power but also provides a longer lifespan compared to conventional bulbs. This reduces the need for frequent replacements and maintenance, contributing to lower long-term operational costs.

4. Performance in Extreme Conditions**: LED explosion-proof lights perform well in extreme temperatures and can operate efficiently in a wide range of environmental conditions. This makes them suitable for various applications, from industrial facilities and chemical plants to oil rigs and mining operations.

5. Cost-Effectiveness : While initial costs might be higher due to their specialized design, the longevity and reduced maintenance requirements of LED explosion-proof lights make them a cost-effective solution over time. Their durability and efficiency contribute to overall savings.

In summary, LED explosion-proof lights are essential for maintaining safety in hazardous environments. Their robust construction, adherence to safety standards, energy efficiency, and performance in extreme conditions make them a reliable choice for preventing accidents and ensuring illumination in risky areas.

Fluorescent Ex-Proof Lights.

Fluorescent explosion-proof lights are engineered specifically for use in hazardous environments where the risk of ignition from traditional lighting is a concern. These environments include areas where flammable gases, vapors, or dust are present, such as in chemical plants, oil refineries, or grain silos. The primary function of explosion-proof lighting is to ensure safety by preventing any potential source of ignition that could lead to an explosion or fire.

The design of these lights incorporates several critical features. First, they have robust, sealed enclosures that protect the internal components from external elements. These enclosures are typically made from high-strength materials like aluminum or stainless steel, which are resistant to corrosion and can withstand harsh environmental conditions. The seals and gaskets used in these enclosures are designed to prevent any entry of dust, water, or other contaminants that could compromise the safety of the lighting system.

Additionally, explosion-proof fluorescent lights are constructed to ensure that any heat or sparks generated inside the fixture do not escape. This is achieved through specific design features, such as explosion-proof housings and internal components that are designed to contain and control heat. The design also includes features like reinforced glass or polycarbonate lenses that can withstand impacts and prevent the release of any fragments or sparks.

These lights are also equipped with specialized ballast and electrical components that are designed to operate safely in hazardous conditions. The ballast is often enclosed in a separate compartment to further reduce the risk of ignition.

Overall, explosion-proof fluorescent lights play a crucial role in maintaining safety in environments where conventional lighting solutions are not suitable. Their design ensures that they can provide reliable illumination without compromising the safety of the environment or its occupants.

Incandescent Explosion-Proof Lights.

Incandescent explosion-proof lights are specialized lighting fixtures designed to provide illumination in hazardous environments where there is a risk of explosive atmospheres. These environments might include industrial settings, oil and gas refineries, chemical plants, and other areas where flammable gases, vapors, or dust are present. The primary function of explosion-proof lights is to ensure safety and prevent ignition of potentially explosive materials.

Design and Construction : Incandescent explosion-proof lights are constructed with robust materials and sealed enclosures to withstand harsh conditions and prevent any potential sparks from escaping. The housing is typically made from heavy-duty metals such as aluminum or steel, and the glass lens is reinforced to handle impact and pressure changes. These lights are also equipped with special gaskets and seals to maintain their integrity in explosive atmospheres.

Functionality : The incandescent bulbs used in these lights generate light by passing an electric current through a filament, which then heats up and produces illumination. The design of explosion-proof lights ensures that the heat generated by the bulb does not exceed safe levels that could ignite surrounding explosive materials. Additionally, the bulb is contained within a protective enclosure that prevents any fragments from escaping if the bulb were to break.

Safety Standards : Incandescent explosion-proof lights must comply with stringent safety standards and certifications, such as those set by the National Electrical Code (NEC) and Underwriters Laboratories (UL). These standards ensure that the lights are tested and verified for their ability to operate safely in hazardous environments.

Applications : These lights are commonly used in a variety of industries including petrochemical, pharmaceutical, and mining. They are essential for maintaining visibility and safety in environments where conventional lighting could pose a risk.

In summary, incandescent explosion-proof lights are crucial for ensuring safety and visibility in hazardous environments. Their rugged design and adherence to safety standards make them suitable for use in high-risk areas where traditional lighting would be unsafe.

HID Ex-Proof Lights.

High-Intensity Discharge (HID) explosion-proof lights are specialized lighting solutions designed for use in hazardous environments where the risk of explosions is significant. These environments can include industrial facilities, oil and gas refineries, chemical plants, and mining operations. The primary objective of HID explosion-proof lights is to provide illumination while ensuring safety and preventing ignition of flammable substances.

Design and Construction:

HID explosion-proof lights are engineered with robust materials to withstand harsh conditions. They typically feature a heavy-duty, explosion-proof enclosure made from materials such as aluminum or stainless steel. This construction helps contain any potential internal explosions and prevents them from igniting surrounding hazardous gases or dust. The glass lens used in these lights is often tempered and designed to resist impacts, further enhancing safety.

Lighting Technology:

HID lights use an electrical arc to produce light, creating a very bright and intense illumination. They are known for their high lumen output, which makes them suitable for illuminating large areas. Unlike traditional incandescent bulbs, HID lights are energy-efficient and have a longer lifespan, which reduces the frequency of replacements and maintenance. Common types of HID lamps used in explosion-proof applications include metal halide, high-pressure sodium, and mercury vapor lamps.

Applications and Benefits:

HID explosion-proof lights are crucial in environments where safety is paramount. They provide high-intensity lighting necessary for performing tasks and maintaining visibility in low-light conditions. The explosion-proof design ensures that even if the light itself fails or encounters an issue, it will not pose a risk to the surrounding environment. These lights are also resistant to extreme temperatures and vibrations, making them suitable for use in demanding conditions.

In summary, HID explosion-proof lights are essential for maintaining safety and visibility in hazardous environments. Their durable construction and efficient lighting technology make them a reliable choice for industrial and commercial applications where explosion risks are a concern.

Portable Ex-Proof Lights

Portable explosion-proof lights are essential tools for ensuring safety and visibility in hazardous environments where the risk of explosions is present. These environments include chemical plants, oil rigs, mining operations, and other industrial settings where flammable gases, vapors, or dust could be present.

These lights are designed to prevent ignition of explosive materials by containing any sparks or heat within the light fixture. They feature robust construction, often made from materials like aluminum or stainless steel, which can withstand harsh conditions and impacts. The lens of explosion-proof lights is typically made from toughened glass or polycarbonate, which is resistant to shattering.

The design of portable explosion-proof lights ensures that they meet stringent safety standards, such as those set by the National Electrical Code (NEC) or the International Electrotechnical Commission (IEC). These lights are often classified according to their protection levels, such as Class I, Division 1 or 2, and Class II, Division 1 or 2, depending on the type of hazardous materials they are suited for.

Portability is a key feature, allowing these lights to be easily moved and positioned as needed. They usually come with rugged carrying handles or straps, and some models are equipped with rechargeable batteries, offering flexibility and reducing the need for constant power sources.

In addition to safety, explosion-proof lights are designed to provide effective illumination in challenging conditions. They are available in various brightness levels and beam patterns to suit different needs. Many models also offer features like adjustable stands or mounts, enabling users to direct light precisely where it is needed.

Overall, portable explosion-proof lights are critical for maintaining safety and operational efficiency in hazardous work environments, offering reliable illumination while minimizing the risk of ignition and explosion.

Application of Ex-Proof Lights.

Explosion-proof lights are essential in environments where flammable gases, vapors, or dust are present. Here are some common applications:

- Oil and Gas Industry: Used in drilling rigs, refineries, and storage facilities where explosive atmospheres can occur.

- Chemical Plants: Installed in areas where hazardous chemicals are processed or stored, reducing the risk of ignition.

- Mining Operations: Used in underground mines and surface mining areas to prevent explosions from methane gas or dust.

- Pharmaceutical Manufacturing: Employed in facilities where flammable substances or powders are used.

- Marine Environments: Utilized on ships and offshore platforms where explosive environments can arise from fuel and other substances.

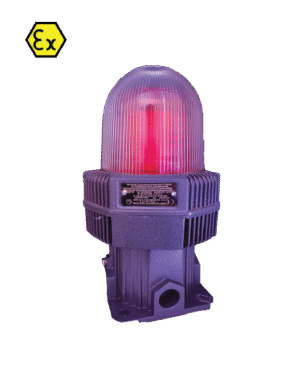

The new state of the art technology Red looks brilliant when turned on, and has been specifically designed for use on wind turbines, buildings & towers providing a wide range of the latest technology available to help maximise safety and operation. Integrated fault monitoring helps proactively detect and analyze problems. With photocell for automatic light on/off according to the condition around and GPS synchronized timing of all the units. Aviation Warning Light

Contact Information:

- Website: Sensor-Control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

As a top-tier Ex-proof products supplier in UAE, Sensor Control LLC is dedicated to powering industries with high-quality motors, ensuring operational excellence and efficiency across the UAE, Saudi Arabia, and the Middle East. Choose Sensor Control LLC, the leading motors supplier in UAE, for all your motor needs.

![Explosion Proof Window Air Conditioner [BKT-2.5 C] [BKT-3.5 C] [BKT-4.5 C]](https://alarmannunciator.ae/wp-content/uploads/2025/02/Artboard-1Explosion-proof-window-air-conditioner-300x383.png)